Specialists in every step of denim manufacture—spinning, dyeing, weaving, washing—abound in Fukuyama, a leading producer of Japan’s high-quality denim. The area’s indigo-dyed yarns and cloth of all types, specialized prints, and wide range of weaves tickle the sensitivities of designers, and Fukuyama products are also a step ahead environmentally. The Hiroshima locale is a driving force behind the worldwide appeal of Japanese denim, accounting for 50 percent of the nation’s total denim manufacture.

Characterized by mild weather and little rainfall, the region has a long history as a settlement. Mountains rise close beyond the shores of the sea. As soil salinity is high the land is not suited to rice cultivation. Cotton, however, is sufficiently salt-tolerant. It was promoted as a crop back in the Edo era by the head of the feudal domain, who introduced textile production as well. Indigo could be grown in the mountainous areas, and dyeing techniques naturally evolved from there. In time the resist-dyed ikat pattern known as Bingo-kasuri, featuring designs resembling the hash mark (#), emerged as a local specialty.

Cotton thread production, dyeing, weaving: such is the background underlying Fukuyama’s ongoing success as a denim production center. Today many different technologies are employed here to meet the demand for high-quality denim fabric in large and small lots. Three companies are especially notable for their love of denim, and for the technical skills they’ve mastered to keep pushing the design envelope. One is Sakamoto Denim, established in 1892, the first in Japan to mechanize the rope-dyeing method.

In rope-dyeing, warp yarns are literally twisted into ropes prior to being dipped in the dye bath. As a result, the core of the threads remains an undyed white. Once woven and washed and worn, over time the colored surface wears away, enhancing the distinctive appeal of faded denim.

Besides innovating a way of mechanizing this dyeing process, Sakamoto also developed the first continuous dyeing machine in Japan. The company is a driving force of Japan’s indigo-dyeing industry; indigo textiles account for 90 percent of its business. Its greatest strength is its wide range of denim colors.

Even “indigo” itself comes in a multitude of hues—the warp threads may be dark indigo, super-dark indigo, natural-plant indigo, greenish indigo, and so on. The company can provide exactly the color a client requires. Sakamoto is also a strong presence in the environmentally sustainable practices that support Fukuyama denim. The company uses electrolyzed water to dye at room temperature, and was one of the first to recycle water through activated sludge processing.

A second Fukuyama maker is Sanyo Senko, a dye-works company that specializes in coloring cloth rather than thread. It handles both continuous and batch dyeing in small and large lots, and particularly excels at discharge dyeing.

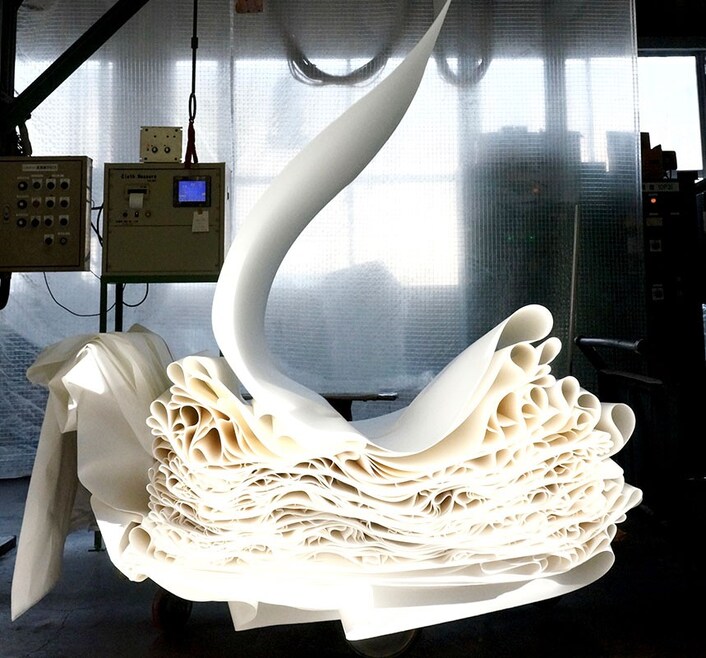

Known as bassen in Japan, discharge dyeing achieves varied effects through repeated bleaching or other chemical processing that subtracts color from dyed fabrics in different patterns and complex designs. A laser-engraved design is run through a rotary printer from which the bleach or other chemical discharge liquid is dispensed, deactivating the color. The pattern emerges once the cloth is steamed and washed. Bassen is essentially ikat printing in its most modern guise.

Bassen offers a wide range of expression, with complicated gradations. The more complex designs are beyond the capacity of machines, and must instead be left to the instincts and eyes of experienced artisans who adjust the printing as necessary, by even a mere millimeter or so.

Shinohara Textile, whose specialty is weaving, is a third great force behind Fukuyama denim. Thorough production control ensures that each thread is perfectly in place to make denim of the finest quality. Shinohara is perhaps best known for Tencel denim.

Tencel is made mostly from the cellulose pulp of eucalyptus plants. Natural, sustainable, and breathable, the material is amazingly soft and smooth. Tencel denim is absorbent and well suited for wear by children and others with sensitive or delicate skin.

The weaving experts at Shinohara blend Tencel with cotton, linen, wool, polyester, and other fibers. A Tencel / cotton blend looks like regular denim but is smooth to the touch. Combined with polyester, Tencel yields denim with a fine sheen and elasticity. Shinohara offers more than 100 varieties of denim weaves, more than you’ll find anywhere else in the world. Try on a pair of jeans made of 100 percent Tencel and you may never want to wear anything else—they are that smooth and light.

Further information on all three of the companies featured here can be found on their websites.